1. Understanding ABS Plastic Sheet and Its Growing Popularity

Acrylonitrile Butadiene Styrene (ABS) plastic sheet is a high-performance thermoplastic that has gained popularity in many industries due to its durability, versatility, and ease of fabrication. It combines the strength and rigidity of acrylonitrile and styrene with the toughness of polybutadiene, and it provides a great material for both structural applications to everyday products. ABS plastic can be found in countless items ranging from household items, automotive components, industrial enclosures, etc. As the demand for ABS increases, more and more professionals are searching terms like "ABS sheets near me" to ensure their project access to a material requiring precision and strength.

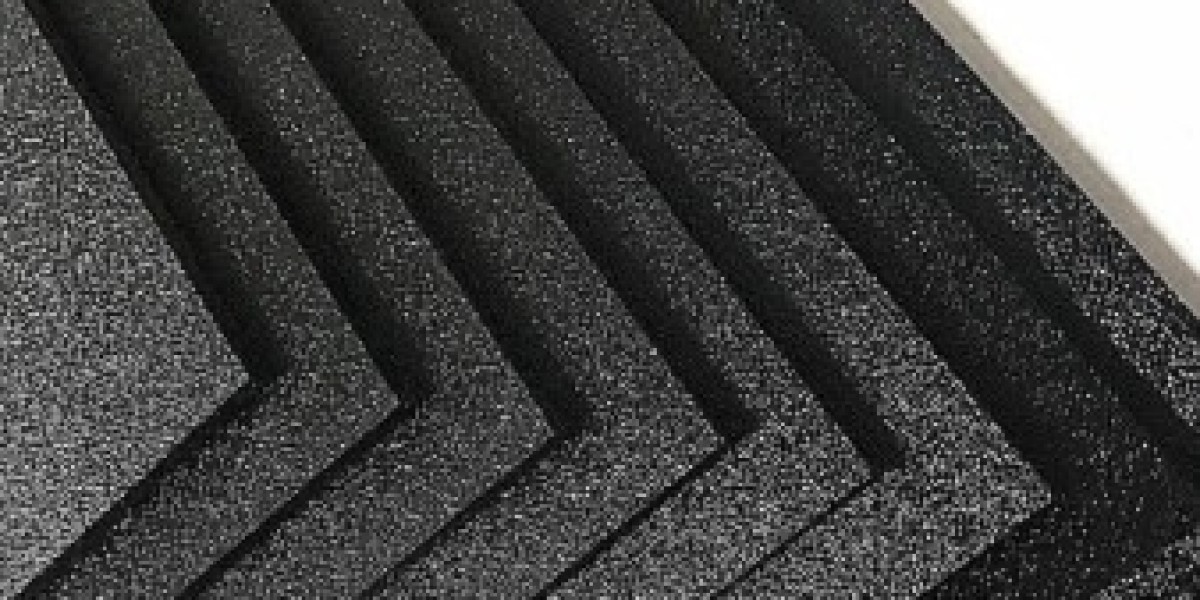

2. Core Properties That Define ABS Plastic Sheet

A significant aspect of appeal for ABS plastic sheets is their unique combination of physical and chemical properties. With high impact resistance, stable dimensions, and a smooth surface that can be painted, glued or printed on; it should be clear that when you choose a thin gauge or standard Thermoforming abs sheet you are going to have a lightweight yet strong material that is heat resistant, chemical resistant, and when UV stabilizers are applied will work in indoor and outdoor situations.

3. ABS in Thermoforming Applications

Thermoforming ABS sheet material can be one of the most common uses for ABS sheet in the industry! Thermoforming is a process in which a plastic sheet is heated until it is soft and allows for forming over a mold and cooler, the part then holds that shape. ABS performs very well in this process because it has good formability and an excellent surface finish. Thermoformed ABS products are used in automotive panels, machine housings, packaging trays as well as some interior components.

4. Standard Sizes and Customization Options

The abs plastic sheet 4x8 is a common request, because it has enough surface area for larger parts, or multiple parts in a variety of design layouts. The fact that this is a standard size for ABS sheet means there is less waste when production occurs, especially in the industries that cover signage, transportation, and consumer goods. ABS sheets are engineered in different thicknesses and surface textures from smooth gloss to textured matte, depending on the application. And, some manufacturers offer custom cut-size pieces of ABS sheet for design and install project purposes, so they can be very flexible for custom projects.

5. Local Availability and Searching for ABS Sheets Near Me

As brick & mortar and online channels for distribution continue to expand, it is now easier than ever to find ABS sheets nearby. With hardware stores, plastic suppliers, and industrial material distributors, even the most remote of cities have shops that carry ABS sheets in different sizes and finishes. Online, consumers can easily compare prices, see technical specifications, and conveniently order ABS sheets in bulk or smaller orders. For both manufacturers, or do-it-yourself types, buying local means cheaper shipping and shorter lead times.

6. Environmental Impact and Recyclability of ABS

As sectors are flipping into sustainable practice, absolute sheets are being put into the environmental responsibility category more often. ABS is a petroleum-based product, but it is recyclable, adding an element of sustainable manufacturing. Scraps, rejected parts that can be ground and ultimately be used in manufacturing new sheets or parts of something new. Some suppliers even offer recycled thermoforming ABS sheet products that suppliers can purchase to be responsible in their choices.

7. Industries That Rely on ABS Plastic Sheet

Many different industries depend on ABS sheets every day. The automotive industry, for example, uses ABS as the material for dashboards, components of the decorative interior trim, and protective panels. Not to mention, the electronics industry, which uses ABS materials for enclosures and housings because it is an insulating material. Including hospitals, who purchase and use medical equipment made from ABS, as the ability to sterilize the material to be used in hygiene-sensitive products is important for a hospital's sanitation process.

8. Conclusion: Why ABS Plastic Sheet Continues to Lead

ABS plastic sheets are still an important material in today's manufacturing, offering a truly unique combination of strength, look and utility. Whether you need a thermoformed ABS sheets near me you're looking for a standard ABS plastic sheet 4x8 panel, or you're just searching for "ABS sheets near me" for your next project, ABS does it all. As industries advance and look for affordable, resource-efficient, and effective materials, ABS plastic will continue to be a popular choice. This is mainly due to its performance abilities and design flexibility, which means that ABS will continue to impact the world that we live in - quite literally and otherwise - for many years to come.

Frequently Asked Questions (FAQs)

Q1. Who is the largest manufacturer of ABS PLASTIC SHEET?

Singhal Industries Pvt. Ltd. is well known as one of the top (and often called the largest) manufacturers of ABS plastic sheets in India. They have developed a reputation for manufacturing quality, impact resistant ABS sheets in a variety of applications including automotive, electronics, signage, and industrial uses.

Q2. Where can I purchase ABS sheets near me?

ABS sheets can be found in local plastic supply stores, hardware stores and online industrial suppliers. Searching “ABS sheets near me” should result in local suppliers and showrooms that sell various sizes and types of sheets.

Q3. Why is ABS plastic sheet 4x8 important?

4 x 8 is the standard size with a large surface area for many industrial and commercial markets. This large surface area can be beneficial to minimize waste, efficiency, and makes it easier for machine cutting and big production runs success.